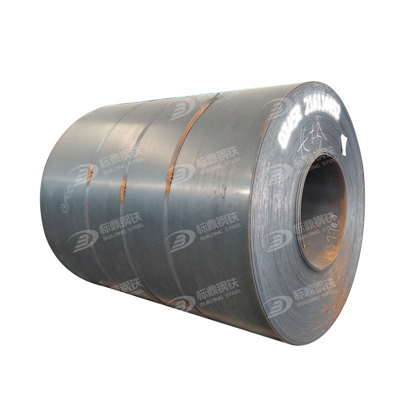

In order to enhance the corrosion - resistance performance of steel pipes, general steel pipes are galvanized. Hot - dip galvanized pipes make the molten metal react with the iron matrix to form an alloy layer, thus combining the matrix and the coating layer. For hot - dip galvanizing, the steel pipes are first pickled to remove the iron oxide on their surfaces. After pickling, they are cleaned in an aqueous solution of ammonium chloride or zinc chloride or a mixed aqueous solution of ammonium chloride and zinc chloride, and then sent into the hot - dip galvanizing tank. Hot - dip galvanizing has the advantages of uniform coating, strong adhesion and long service life. Complex physical and chemical reactions occur between the steel pipe matrix and the molten plating solution, forming a corrosion - resistant and tightly - structured zinc - iron alloy layer. The alloy layer, the pure zinc layer and the steel pipe matrix are integrated, so it has strong corrosion - resistance. In addition, hot - dip galvanized pipes can also undergo various preliminary processing operations, such as cutting, drilling, welding, threading, reducing diameter, etc., and are widely used.

022-8383 6336

022-8383 6336 Time:2024-07-23

Time:2024-07-23 Location:

Location:![C_QRP(]S)5AXMRI$8@E}RLG.png](/../FileUpLoad/UEditorUploadFile/upload/image/20240723/6385733259694440838456462.png)