- Home

- About

-

Products

- Welded Steel Pipe

- Hot Rolled Welded Round Pipe

- Annealing Welded Round Pipe

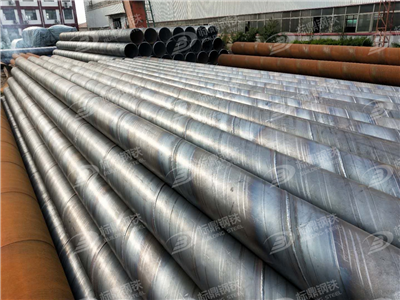

- Spiral Welded Round Pipe

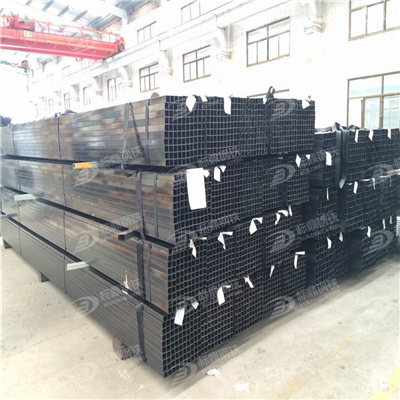

- Hot Rolled Square And Rectangular Tube

- Galvanized Steel Pipe

- Hot Dipped Galvanized Steel Pipe

- Pre Galvanized Steel Pipe

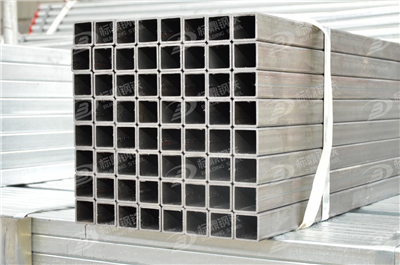

- Hot Dipped Galvanized Square And Rectangular Tube

- Pre Galvanized Square And Rectangular Tube

- Seamless Steel Pipe

- Carbon Steel Seamless Pipe

- Stainless Steel Seamless Pipe

- Aluminium Steel Seamless Pipe

- PVC Pipe

- Scaffolding

- Ringlock Scaffolding System

- Cuplock Scaffolding System

- Frame Scaffolding System

- Coupler Scaffolding System

- Advantages

- News

- Contact

-

- Welded Steel Pipe

- Hot Rolled Welded Round Pipe

- Annealing Welded Round Pipe

- Spiral Welded Round Pipe

- Hot Rolled Square And Rectangular Tube

- Annealing Square And Rectangular Tube

- Welded Profiled Pipe

- Stainless Steel Welded Pipe

- Aluminium Welded Pipe

- Galvanized Steel Pipe

- Hot Dipped Galvanized Steel Pipe

- Pre Galvanized Steel Pipe

- Hot Dipped Galvanized Square And Rectangular Tube

- Pre Galvanized Square And Rectangular Tube

- Seamless Steel Pipe

- Carbon Steel Seamless Pipe

- Stainless Steel Seamless Pipe

- Aluminium Steel Seamless Pipe

- PVC Pipe

- Profiles

- Angle Bar

- Flat Bar

- Channel

- Round Bar

- Square Bar

- Rebar

- I Beam And H Beam

- Steel Plate

- Corrugated Roofing Sheet

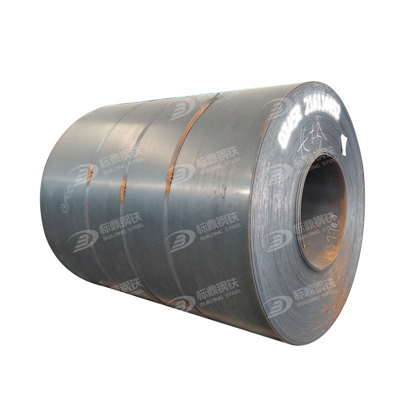

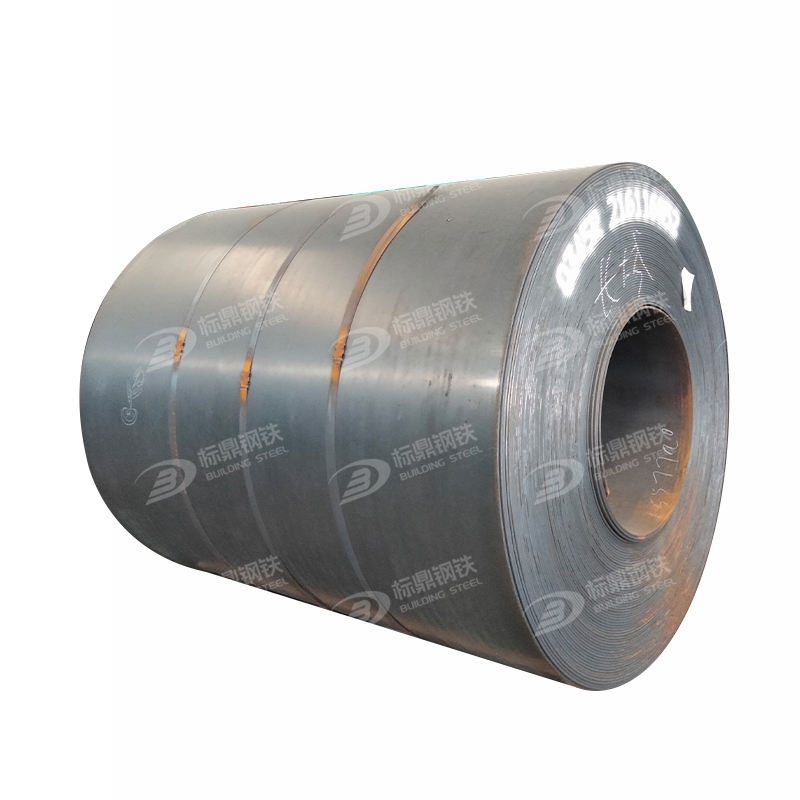

- Steel Coils

- Hot-Rolled Coil

- Cold-Rolled Coil

- Galvanized Coil

- Aluminized Zinc Coil

- PPGI Coil

- Stainless Steel Coil

- Aluminium Coil

- Wire Mesh

- Wire

- Reinforcing Mesh

- Welded Wire Mesh

- Chain Link Fence

- Expanded Metal Mesh

- Perforated Metal Mesh

- Crimped Wire Mesh

- Steel Grating

- Barbed Wire

- Scaffolding

- Ringlock Scaffolding System

- Cuplock Scaffolding System

- Frame Scaffolding System

- Coupler Scaffolding System

- Scaffolding Plank

- Steel Prop

022-8383 6336

022-8383 6336 Time:2024-07-26

Time:2024-07-26 Location:

Location: